CNC Waterjet Cutting Machines - Jetlite 3020

Overview

KELPE manufactures complete CNC Waterjet Cutting Machines fitted with industry standard high pressure waterjet pumps and abrasive delivery systems. The JetLite series provides a low cost solution for CNC waterjet cutting of practically any material. The main features are:

Precise positioning with 0.1mm resolution is achieved by the combination of an embedded closed loop real time controller and servo controlled ball screw and rack drives on the X, Y and Z axes. Once the cutting plan is prepared offline using the True Shape Nesting Software provided, the CNC file is transferred to the machine by means of a CD, USB or WLAN interface. The operator can then execute and monitor the program using a very simple, easy to use graphical user interface provided on a 19″ LCD monitor. Marking is not required and the exact cutting progress is displayed on screen. During the cutting operation, operator input is minimized by the Auto-Ignition, Remote Flame/Arc On/Off Control and Auto Torch Height Control facilities provided.

- Precision Ball Screw Drives on all Axes

- MITSUBISHI(Japan) AC Servo Controls

- Hardened and Ground LM Guideways on all Axes

- Graphical User Interface with 19″ LCD Display

- True Shape Nesting

- Independent Stainless Steel Tank Construction

- Wide Gantry Designed for Ease of Access and Loading

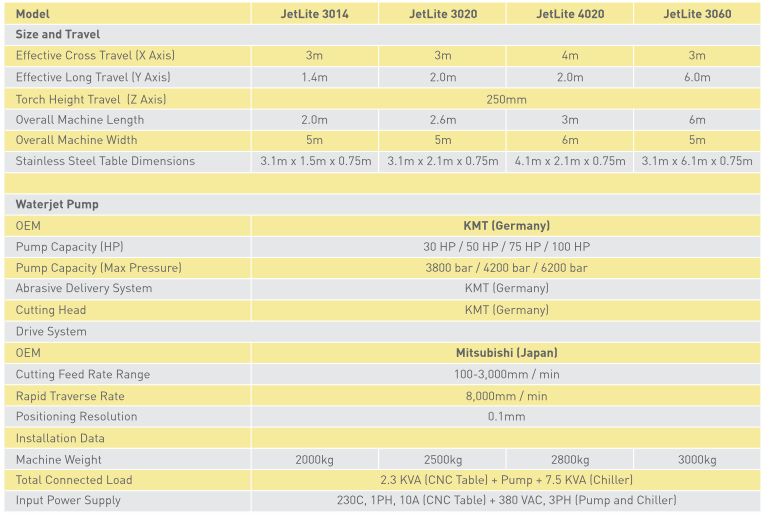

- Choice of High Pressure Pumps

Features

- MITSUBISHI (Japan) Electronic Controls

- Precision Ball Screw Drives on all Axes

- Choice of KMT (Germany) High Pressure Pumps

- KMT (Germany) make Cutting Head and AMS

- Hardened and Ground LM Guide ways on all Axes

- 19 inch LCD Display and True Nesting Software